Introduction: What is Lean Management in Healthcare?

Lean management is a methodology that originated in the manufacturing industry, particularly with the Toyota Production System, but has since been successfully adapted across multiple sectors, including healthcare consulting firms and hospital staffing services. At its core, Lean management in healthcare on eliminating waste, optimizing processes, and continuously improving operations to deliver more value to the end customer—in healthcare, this means the patient.

In a healthcare setting, Lean principles aim to streamline workflows, reduce delays, eliminate redundant steps, and ensure resources are allocated effectively. By focusing on value from the patient’s perspective, Lean helps organizations improve care quality, increase efficiency, and reduce costs—all while empowering staff to contribute to problem-solving and innovation. These practices support broader healthcare workforce solutions and align with goals of healthcare operational excellence.

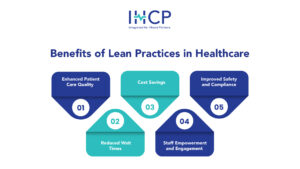

Benefits of Lean Practices in Healthcare Organizations

Implementing Lean management in healthcare settings offers numerous advantages, both operational and clinical:

- Enhanced Patient Care Quality

By eliminating inefficiencies and reducing errors, healthcare teams can focus more on delivering high-quality, patient-centered care. This directly complements healthcare process improvement initiatives. - Reduced Wait Times

Lean process mapping identifies bottlenecks, enabling faster patient flow in areas such as emergency departments, diagnostic imaging, and surgical units. - Cost Savings

Streamlined workflows reduce unnecessary resource use, lower inventory costs, and minimize overtime expenses—vital for both large hospitals and smaller facilities seeking healthcare efficiency strategies. - Staff Empowerment and Engagement

Lean encourages frontline staff to identify problems and propose solutions, fostering a culture of ownership and accountability. This emphasis on staff empowerment in healthcare improves morale and retention. - Improved Safety and Compliance

Standardized processes reduce variability, lowering the risk of medical errors and enhancing regulatory compliance.

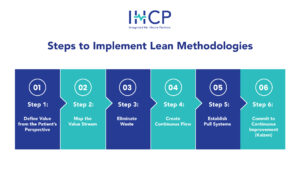

Steps to Implement Lean Methodologies in Hospitals and Clinics

Implementing Lean in healthcare requires a structured, organization-wide approach that fits alongside medical staffing solutions and other continuous improvement in healthcare strategies:

Step 1: Define Value from the Patient’s Perspective

Identify what matters most to patients—such as shorter wait times, accurate diagnoses, and clear communication—and align all processes to deliver those outcomes.

Step 2: Map the Value Stream

Document every step of a process, from patient intake to discharge, to identify waste and non-value-added activities.

Step 3: Eliminate Waste

Apply the “Eight Wastes” framework—defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion, and extra-processing—to remove inefficiencies. This is essential for reducing waste in hospitals.

Step 4: Create Continuous Flow

Reorganize processes so that patients move smoothly through the care pathway without unnecessary delays or handoffs.

Step 5: Establish Pull Systems

Provide services and resources based on patient demand rather than forecasting, reducing overproduction and inventory waste.

Step 6: Commit to Continuous Improvement (Kaizen)

Encourage small, incremental changes over time, driven by staff feedback and performance metrics.

Overcoming Resistance to Change in Healthcare Process Improvement

One of the greatest challenges in implementing Lean is overcoming skepticism and resistance from staff who are accustomed to established processes. This is a common theme in many healthcare staffing challenges as well.

- Communicate the “Why”

Explain how Lean benefits both patients and staff—reducing workload stress, improving outcomes, and increasing job satisfaction. - Involve Staff Early

Include frontline workers in the planning and design phases. Their hands-on experience provides invaluable insight into operational inefficiencies. - Provide Training and Support

Offer workshops and on-the-job coaching to ensure staff understand Lean principles and feel confident applying them. - Celebrate Early Wins

Highlight quick, visible improvements to build momentum and demonstrate that Lean delivers real results. - Lead by Example

Leadership should model Lean thinking by actively participating in process improvement initiatives, supported by healthcare recruitment consulting and organizational leadership teams.

Conclusion: Continuous Improvement for Quality Care in Healthcare Systems

Lean management in healthcare is not a one-time project—it is a mindset and an ongoing commitment to continuous improvement in healthcare. When implemented effectively, Lean can transform healthcare organizations by streamlining workflows, empowering staff, reducing waste, and enhancing patient experiences.

By embedding Lean principles into everyday operations, healthcare providers can build a more resilient, efficient, and patient-focused system—one that adapts to challenges and evolves with the changing needs of the communities they serve. Lean also complements broader strategies such as supply chain management consulting, healthcare workforce solutions, and other forms of operational excellence in healthcare.

At IHCP, we help healthcare organizations adopt and sustain Lean methodologies that improve efficiency, reduce costs, and elevate patient care. From process mapping to staff training and change management, our team ensures Lean becomes a sustainable part of your culture.

Visit www.integratedhcp.com to learn how we can help you implement Lean principles that drive measurable results.

FAQs: Lean Healthcare Practices and Workforce Efficiency

- What is Lean management in healthcare?

Lean management in healthcare is an approach focused on eliminating waste, streamlining processes, and continuously improving operations to deliver greater value to patients while optimizing resources and reducing costs. - How does Lean improve patient care?

By removing inefficiencies and standardizing workflows, Lean allows healthcare teams to focus more time and attention on direct patient care, which leads to better outcomes, reduced errors, and higher patient satisfaction. - What are common examples of waste in healthcare?

Typical waste includes unnecessary patient transfers, duplicate paperwork, overstocked supplies, long wait times, underutilized staff skills, and excessive movement of people or materials within a facility. - How long does it take to see results from Lean implementation?

Some improvements, like reduced wait times or streamlined documentation, can be seen within weeks. More comprehensive transformations may take several months to a year, depending on the complexity of the processes. - Is Lean only applicable to large hospitals?

No. Lean principles can be applied in any healthcare setting—from small clinics and private practices to large hospital systems—by tailoring methods to the scale and scope of operations.